-

Hot

ASTM D5800 Evaporation Loss Of Lubricating Oils By The Noack Method

The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable evaporation loss. Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications.

Send Email Details -

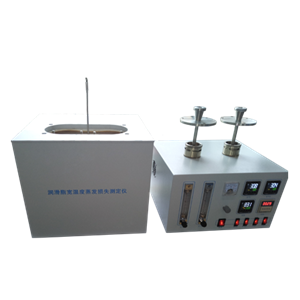

ASTM D2595 Lubricating Grease Wide Temperature Range Evaporation Loss Tester

KN-2595 Lubricating Grease Wide Temperature Range Evaporation Loss Tester conforms to ASTM D2595 Standard Test Method for Evaporation Loss of Lubricating Greases Over Wide-Temperature Range. A weighed sample of grease in an evaporation cell is placed in a heating device maintained at the desired test temperature. Heated air is passed over the grease surface for 22h±0.1h. The loss in weight of the sample due to evaporation is determined.

Send Email Details -

ASTM D130 Metal Bath Copper Strip Corrosion Tester

KN-130J Metal Bath Copper Strip Corrosion Tester conforms to the ASTM D130 Standard Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test and ASTM D4048 Standard Test Method for Detection of Copper Corrosion from Lubricating Grease. This tester is suitable for testing aviation gasoline, jet fuel, motor gasoline, natural gasoline, or other hydrocarbons with Reid vapor pressure not exceeding 124kPa (930mmHg), solvent oil, kerosene, diesel, distillate fuel oil, lubricating oil, grease, and other petroleum product.

Send Email Details -

ASTM D4048 Copper Corrosion From Lubricating Grease

A prepared copper strip is totally immersed in a sample of grease and heated in an oven or liquid bath at a specified temperature for a definite period of time. Commonly used conditions are 100 6 1°C (212 6 2°F) for 24 h 6 5 min. At the end of this heating period, the strip is removed, washed, and compared with the Copper Strip Corrosion Standard.

Send Email Details -

ASTM D1838 Copper Strip Corrosion By Liquefied Petroleum (LP) Gases

Copper corrosion limits provide assurance that difficulties will not be experienced in deterioration of the copper and copper-alloy fittings and connections that are commonly used in many types of utilization, storage, and transportation equipment.

Send Email Details -

ASTM D1384 Corrosion Test For Engine Coolants In Glassware

this test method will generally distinguish between coolants that are definitely deleterious from the corrosion standpoint and those that are suitable for further evaluation.however, the results of this test method cannot stand alone as evidence of satisfactory corrosion inhibition. the sctual serivice value of an engine coolant formulation can be determined only by more comprehensive bench,hynamometer,and field tests

Send Email Details -

ASTM D323 Automatic Reid Vapor Pressure Bath

Vapor pressure is an important physical property of volatile liquids. This tester is used to determine the vapor pressure at 37.8°C (100°F) of petroleum products and crude oils with initial boiling point above 0°C (32°F). Vapor pressure is critically important for both automotive and aviation gasolines, affecting starting, warm-up, and tendency to vapor lock with high operating temperatures or high altitudes. Maximum vapor pressure limits for gasoline are legally mandated in some areas as a measure of air pollution control.

Send Email Details -

ASTM D2782 Timken Load Tester

The Tester is made up of a 1.5 kw (0-1500r/Min) Servo motor, a digital speed indicator, a temperature controller, an electronic time relay, an electrical box and a Servo speed regulating system, a lubricating system and a heating device, a force applying device, a sample and accessories.

Send Email Details