ASTM D5800 Evaporation Loss Of Lubricating Oils By The Noack Method

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate.

Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable

evaporation loss. Some engine manufacturers, when specifying a maximum

allowable evaporation loss, quote this test method along with the specifications.

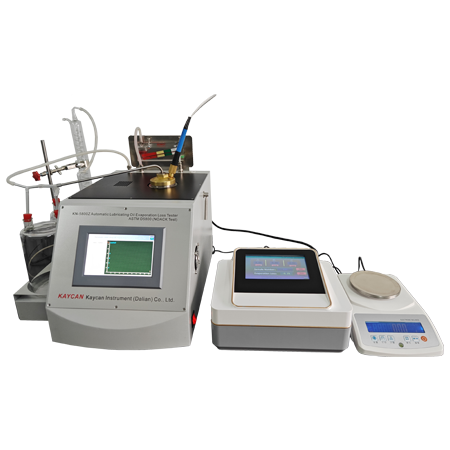

KN-5800Z Automatic Lubricating Oil Evaporation Loss Tester (NOACK Volatility Test)

Overview

KN-5800Z Automatic Lubricating Oil Evaporation Loss Tester (NOACK Volatility Test) conforms to ASTM D5800 Standard Test Method for Evaporation Loss of Lubricating Oils by the Noack Method, Procedure B uses the automated non-Woods metal Noack evaporative apparatus. The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. , which is suitable for the determination of lubricating oil (especially Evaporation loss of engine oil) and lubricating base oil at 250 ℃.

Main Technical Features

1. Metal bath heating device, safe and environmentally friendly.

2. Imported differential pressure gauge to ensure accurate pressure.

3. Woods alloy is added to the bath body for better heat transfer.

4. Equipped with special vacuum suction system.

5. Digital timer to record test time.

6. The evaporation crucible meets ASTM standards.

7. Precision pressure regulation system and imported needle valve to ensure accurate flow regulation.

8. There is a gas buffer bottle inside.

9. High-power solid state relay control heater.

10. Imported temperature control gauge for precise control.

11. Be able to get the dedicated balance data from the data processing system, with printing function

Technical Parameters

Working power supply | AC (220±10%) V, 50Hz(customizable) |

Temperature control mode | Digital display PID temperature control |

Temperature control range | Normal temperature to 250 °C ± 0.1 ° |

Heating method | Metal bath heating |

Pressure regulation | Highly precise needle valve |

Suction method | Vacuum pump |

Differential pressure measurement | Differential pressure measurement |

Applicable test standard | ASTM D5800,procedure B |