-

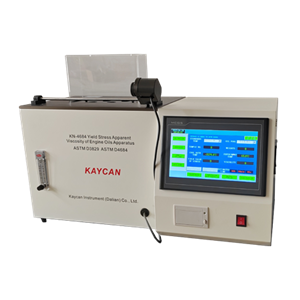

ASTM D4684 Yield Stress And Apparent Viscosity Of Engine Oils

An engine oil sample is held at 80°C and then cooled at a programmed cooling rate to a final test temperature and held for a specified time period. At the end of this period, a series of increasing low torques are applied to the rotor shaft until rotation occurs to determine the yield stress, if any is exhibited. A higher torque is then applied to determine the apparent viscosity of the sample.

Send Email Details -

ASTM D5481 Apparent Viscosity At High Temperature And High Shear Rate By Multicell Capillary Viscometer HTHS

High-Temperature and High-Shear Rate Apparent Viscosity Tester (HTHS) covers the laboratory determination of high-temperature high-shear (HTHS) viscosity of engine oil at a temperature of 150℃ using a multicell capillary viscometer containing pressure, temperature, and timing instrumentation. The shear rate for this test method corresponds to an apparent shear rate at the wall of 1.4 million reciprocal seconds (1.4 3 106s-1).This shear rate has been found to decrease the discrepancy between this

Send Email Details -

Hot

ASTM D4683 Viscosity At High Temperature And High Shear Rate By Tapered Plug Viscometer

KN-4683 Apparatus for Viscosity by TBS conforms to ASTM D4683 Standard Test Method for Measuring Viscosity of New and Used Engine Oils at High Shear Rate and High Temperature by Tapered Bearing Simulator Viscometer at 150 °C and ASTM D4741 Standard Test Method for Measuring Viscosity at High Temperature and High Shear Rate by Tapered-Plug Viscometer. The ASTM D4683 covers the laboratory determination of the viscosity of engine oils at 150℃ and 1.0·106s-1 using a viscometer having a slightly tape

Send Email Details -

ASTM D2170 Viscosity Of Asphalts By Vacuum Capillary Viscometer

the kinematic viscosity characterizes flow behavior. the method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. the specifications are usually at temperature of 60 and 135℃.

Send Email Details -

-

ASTM D2171 Apparatus for Viscosity of Asphalts

KN-2171 Apparatus for Viscosity of Asphalts conforms to ASTM D2171 Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer. The viscosity at 60℃ characterizes flow behavior and may be used for specification requirements for cutbacks and asphalt binders. This time is measured for a fixed volume of the liquid to be drawn up through a capillary tube by means of vacuum, under closely controlled conditions of vacuum and temperature. The viscosity in Pascal-seconds is calculated by multiplying the flow time in seconds by the viscometer calibration factor.

Send Email Details -

ASTM D6278 Shear Stability Of Polymer Containing Fluids

This test evaluates the percent viscosity loss for polymer-containing fluids resulting from polymer degradation in the high shear nozzle device. Thermal or oxidative effects are minimized.

Send Email Details -

DIN 51350-6 Shear Stability Of Lubricating Oils Containing Polymers

This is KRL friction pair on a four-ball friction tester, uses SKF SKF 32008 tapered roller bearings to determine the shear stability of polymer-containing lubricants, including pressure fluids. The test results can be used to predict the permanent viscosity loss. The tap speed is 1500 rpm, the test force is 5000 Newtons, the temperature is 60 °C, the total number of revolutions is 1.74 million, the time is about 20 hours.

Send Email Details