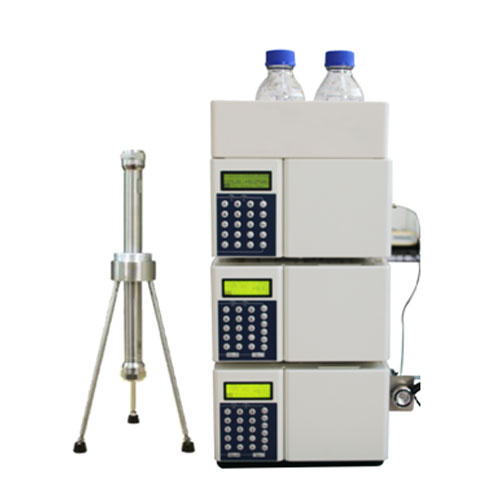

ASTM D5837 Apparatus for Furanic Compounds by HPLC

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER RECEIVING FULL PAYMENT

Supply capacity 30 sets/month

KN-5837 Furanic Compounds by HPLC conforms to ASTM D5837 Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by High-Performance Liquid Chromatography (HPLC). Furanic compounds are generated by the degradation of cellulosic materials used in the solid insulation systems of electrical equipment. Furanic compounds which are oil soluble to an appreciable degree will migrate into the insulating liquid. High concentrations or unusual increases in the concentrations of Furanic compounds in oil may indicate cellulose degradation from aging or incipient fault conditions.

KN-5837 Furanic Compounds by HPLC

Overview

KN-5837 Furanic Compounds by HPLC conforms to ASTM D5837 Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by High-Performance Liquid Chromatography (HPLC). Furanic compounds are generated by the degradation of cellulosic materials used in the solid insulation systems of electrical equipment. Furanic compounds which are oil soluble to an appreciable degree will migrate into the insulating liquid. High concentrations or unusual increases in the concentrations of Furanic compounds in oil may indicate cellulose degradation from aging or incipient fault conditions.

Features:

Reasonable circuit design, much easier door design, cooling system improves stability

Equipped with a new version of the chromatographic workstation Survey that meets GMP certification requirements, upgraded electronic signatures, user rights assignment, audit trail, system adaptability and other functions

Replacement tray design is more beautiful

Improved conductive silicone button design improves touch feeling

Change instrument signal communication method to improve data stability

Upgrade the motherboard to optimize the control program to increase the stability

Technical parameters:

Pumping system

Injection method: Micro-volume tandem double plunger

Maximum injection pressure: 6000psi

Flow rate range: 0.001~9.999ml/min ±0.5% (Step size: 0.001ml/min)

Flow rate stability RSD: ≤0.2%

Pressure fluctuation: ±1% (0~100%, Water / acetone aqueous solution 2 gradient)

Pump sealing: <0.1Mpa, Flow rate: 1ml/min, Pressure drop<5MPa

Time program function: YES

Dimension: W260*H130*D420mm

UV-VIS Spectrophotometric Detector

Wavelength: 190~700nm±1nm

Wavelength reproducibility: ≤0.1nm

Linearity range:≥104

Spectral bandwidth: 6nm

Flow cell volume:10μL

Optical path: 10mm

Time program function; YES

Dynamic Noise:≤±0.75×10-5AU (Methanol, 1ml/min, 254nm, 20°C)

Static Noise: ≤±0.5×10-5AU(Empty pool, Response time 1 s, 20 °C)

Dynamic Drifting:≤±1×10-4AU (Methanol, 1ml/min, 254nm, 20°C)

Static Drifting:≤±0.5×10-4AU(Empty pool, Response time 1 s, 20 °C)

Minimum concentration detection: ≤4×10-9g/ml(Naphthalene / methanol solution)

Qualitative repeatability RSD≤0.1%,Quantitative repeatability RSD≤0.5%