ASTM D3612 Dissolved Gases In Transformer Oil By GC TOGA

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

Transformer oil is a highly refined mineral oil used in electrical transformers. It has excellent insulating properties, suppresses corona and arcing, and serves as a coolant. In case of electrical errors, the oil breaks down to gases, which identity and content can be related to the type and severity of the electrical fault. This information is very useful in the preventative maintenance program.

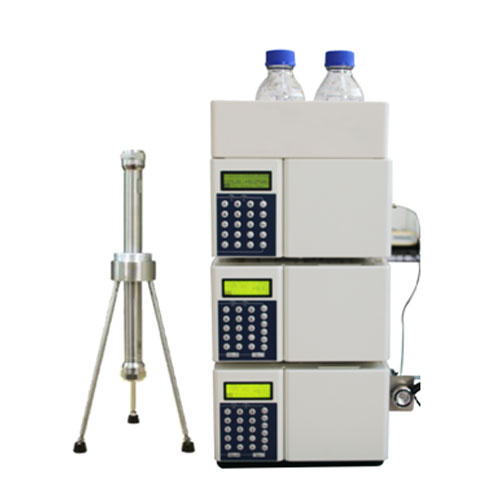

KN-3612 GC for Analysis of Dissolved Gases in Transformer Oil (TOGA)

Introduction

KN-3612 TOGA conforms to ASTM D3612 Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography. It is used for the measurement of gases dissolved in electrical insulating oil having a viscosity of 20 cSt (100SUS) or less at 40℃ (104℉)

Oil and oil-immersed electrical insulation materials may decompose under the influence of thermal and electrical stresses, and in doing so, generated gaseous decomposition products of varying composition which dissolve in the oil. The nature and amount of the individual component gases that may be recovered and analyzed maybe indicative of the type and degree of the abnormality responsible for the gas generation of specific gases over time are also used to evaluate the condition of the electric apparatus.

Background

An electrical and thermal loads are applied to transformers, the insulator oil and various components can undergo decomposition, the byproducts of which are dissolved into the transformer oil as gaseous compounds. Analysis of these gases, called dissolved gas analysis (DGA), is a common analysis performed on insulator oil sampled from electrical transformers that can indicate the health, longevity, and potential error states of transformers. Given the large and growing number of transformers associated with modern electrical infrastructure, limited throughput for the large number of received samples is a common issue faced by testing labs. ASTM D3612 Method C specifies the use of automated headspace sampling of the transformer oil, which allows for higher throughput over other sampling methods for DGA analysis, such as vacuum extraction or the use of a stripper column (e.g., ASTM D3612 Methods A and B, respectively)

Features

The TOGA adopts Ethernet communication interface, which can easily form a local area network to achieve long-distance data transmission, remote control and remote diagnosis.

It has powerful and perfect power-on self-diagnosis function, intuitive display of fault information, power failure storage protection function and anti-power interference function

Adopts transformer oil special anti-pollution composite column technology greatly improves the service life of the column

The instrument has undergone strict aging tests before leaving the factory, and the parameters have been set, and the user only needs to perform a simple start-up operation

|  |

| Small dead volume Injection system | High-precision gas flow control system |

Parameters

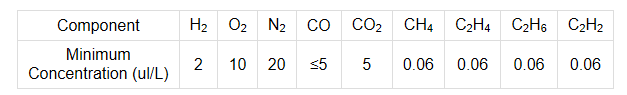

1ml Injection volume, the minimum detected concentration (ul/L)

Ambient requirements: 0~40℃

Accuracy: ±0.1℃

Temperature control range: Ambient+5℃~450℃

Analysis cycle: 7min

Power: 1.9KW

Dimension: 660*560*480mm

|  |

| High efficiency conversion device | FID(High sensitivity and low noise) |

Main technical parameters:

Real-time computer control and data processing

The TOGA can expand the 10/100M Ethernet interface, and can be connected to the TOGA through the computer in the local area network to realize remote data acquisition and management. Increases the freedom of the device and promotes efficient application in the laboratory.

Through the user-friendly software operation interface, it is very convenient for users to set parameters including temperature, range rise, event, detector and so on; Intuitive operation includes functions such as FID automatic ignition, TCD switching bridge flow, turning on and off temperature control, turning on and off the rise and closing of the range and various time events

The unique design of gasification chamber and detector ensures the stability and convenient maintenance of the TOGA

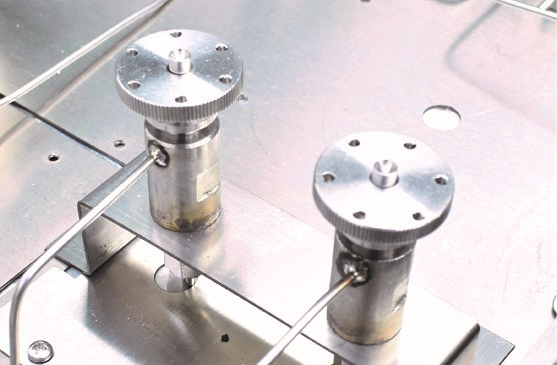

The unique inlet design solves injection bias, and the dual-column compensation function not only solves the baseline drift caused by the program heating, but also reduces the influence of background noise, which can achieve lower detection limits

Unique vaporization chamber design, smaller dead volume; The replacement of injection pads, liners, polarizing poles, collecting poles, nozzles and other accessories can be replaced easily; Filling columns, capillary injectors, TCD, FID detectors and other main replacements can be completely disassembled with only one wrench, which is very convenient for maintenance.

High precision and stable temperature control system

The main control circuit adopts advanced microprocessor, large-capacity FLASH and EEPROM memory, so that the data preservation is more reliable; The integrated design of the circuit board integrating measurement, control and power supply improves the anti-interference and reliability of the TOGA

Adopts the temperature control circuit of the microprocessor, the temperature accuracy of the controlled object in each heating zone reaches 0.1℃

The column chamber has a double overtemperature protection device. If the temperature exceeds the setting, the instrument stops heating up and reports the fault on the display

The intelligent double rear door technology ensures that the TOGA can have good temperature control accuracy when the column chamber temperature is close to room temperature, and can quickly cool down

Twenty-step programmed heating to accommodate the analysis of complex samples with wide boiling points

Simple operation interface

Adopts 7-inch LCD display and supports capacitive touch, which is intuitive and easy to operate;

Self-diagnosis function and display of the fault site;

Data power-off protection function, the operating data set by the TOGA can be stored for a long time after the power failure

Protection

Will stop heating when there is no carrier gas, so as to protect the column and thermal conductivity cell

Auto ignition

It is able to set the time for automatic ignition, and at the same time has the function of fire extinguishing hydrogen protection

Main technical parameter

Temperature control parameter

Column Oven: Ambient+5℃~450℃, Accuracy:±0.1℃

Injector: Ambient+5℃~450℃, Accuracy:±0.1℃

Detector: Ambient+5℃~450℃, Accuracy:±0.1℃

Maximum control 7 paths temperature

Column Oven parameter

Column Oven: Ambient+5℃~450℃, Accuracy:±0.1℃

Volume:260mm*270mm*230mm

Programmed heating: 20 steps

Programmed heating rate: 1~80℃/min (0.1℃ increment)

Retention time of each step: 0~655min (1min increment)

Automatic rear opening design to guarantee the fast cooling speed,

It will only cost within 7min to cool from 350℃ to 50℃

Fan with big power and low noise to guarantee the uniformity of the temperature

Column Oven parameter

Column Oven: Ambient+5℃~450℃, Accuracy:±0.1℃

Volume:260mm*270mm*230mm

Programmed heating: 20 steps

Programmed heating rate: 1~80℃/min (0.1℃ increment)

Retention time of each step: 0~655min (1min increment)

Automatic rear opening design to guarantee the fast cooling speed,

It will only cost within 7min to cool from 350℃ to 50℃

Fan with big power and low noise to guarantee the uniformity of the temperature

Detector

FID

Adopts unique and stable amplifier technology, the signal amplification board has been specially treated to maintain stable operation in harsh conditions

Be suitable for packed column and capillary column

Operation temperature: 450℃

Minimum limit of detection:<5pg c/s (n-Hexadecane)

Linear dynamic range (LDR): 107(±10%)

Data acquisition frequency: 100Hz

Automatic ignition: Auto hydrogen cut off after fire extinguished

TCD

Be suitable for packed column and capillary column

Fast stabilization time, small dead volume, short equilibrium time

Operation temperature: 400℃

Data acquisition frequency: 100Hz

Linear dynamic range (LDR): 105(±10%)

Minimum limit of detection: <800pg propane/ml (Helium)

Others

Dimension: 586*500*530mm

Weight: 46g

Rated voltage: 220V±50Hz, Power≤2.5kW

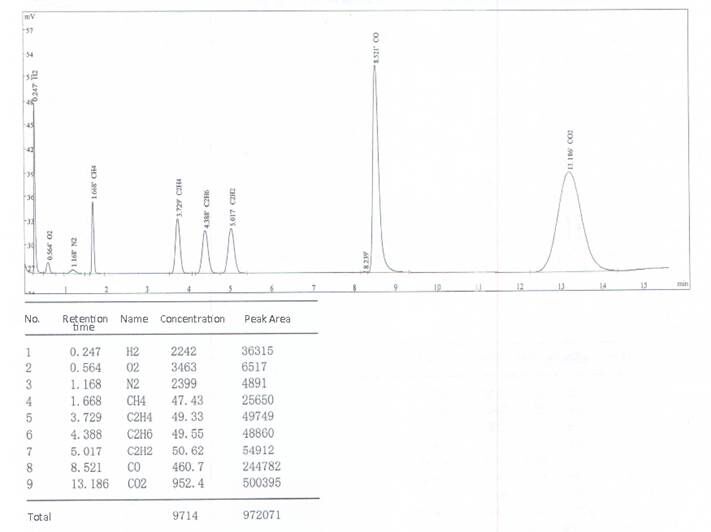

Chromatogram