-

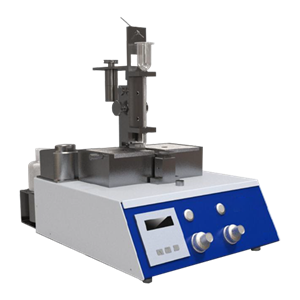

KN-511 Mechanical Impurities Tester

KN-511 Mechanical Impurities Tester conforms to GB/T 511 Petroleum, Petroleum Products and Additives – Method for Determination of Mechanical Admixtures. It applies to test the mechanical impurities of petroleum products and additives by using gravimetric method

Send Email Details -

ASTM D1796 Water And Sediment In Fuel Oils By The Centrifuge Method

The water and sediment content of fuel oil is significant because it can cause corrosion of equipment and problems in processing. A determination of water and sediment content is required to measure accurately net volumes of actual fuel oil in sales, taxation, exchanges, and custody transfers.

Send Email Details -

ASTM D3230 Salts In Crude Oil

KN-3230 Salt Content of Crude Oil Tester conforms to ASTM D3230 Standard Test Method for Salts in Crude Oil (Electrometric Method), it is suitable for the approximate chloride (salts) concentration in crude oil. The range of concentration covered is 0 to 500mg/kg or 0 to 150lb/1000bbl as chloride concentration/volume of crude oil. KN-3230 is suitable for measuring the salt content to detect the total halide value of which the range is 0.002~0.02%(weight) in the crude oil, reduced oil, cracking oil residue and fuel oil, it is also suitable for estimating the seawater pollution situation of the used team turbine oil and bunker fuel oil.

Send Email Details -

ASTM D2699, ASTM D2700 Apparatus for Octane and Cetane Number of Spark-Ignition Engine Fuel

KN-300R Apparatus for Octane and Cetane Number of Spark-Ignition Engine Fuel conforms to ASTM D2699 Standard Test Method for Research Octane Number of Spark-Ignition Engine Fuel and ASTM D2700 Standard Test Method for Motor Octane Number of Spark-Ignition Engine Fuel. It covers the quantitative determination of the knock rating of liquid spark-ignition engine fuel in terms of Research O.N., including fuels that contain up to 25% v/v of ethanol and the quantitative determination of the knock rating of liquid spark

Send Email Details -

ASTM D6595 Portable Rotary Disc Electrode Atomic Emission Spectrometer (RDE-AES)

Wear metals and contaminants in a used oil test specimen are evaporated and excited by a controlled arc discharge using the rotating disk technique. The radiant energies of selected analytical lines and one or more references are collected and stored by way of photomultiplier tubes, charge coupled devices or other suitable detectors. A comparison is made of the emitted intensities of the elements in the used oil test specimen against those measured with calibration standards.

Send Email Details -

ASTM D7684 Dual Analysis Ferrograph

KN-7684 Dual Analysis Ferrograph conforms to ASTM D7684 Standard Guide for Microscopic Characterization of Particles from In-Service Lubricants. Periodic in-service lubricant samples are collected from a machine as part of a routine condition monitoring program. The sample is prepared to separated particles from the sample fluid. The separated particles are subsequently examined using an optical microscope to identify the types of particles present to aid in identifying the wear mode occurring in the oil-wetted path of the machine

Send Email Details -

ASTM D7690 Thistle Tube Iron Spectrometer

KN-7690 Thistle Tube Iron Spectrometer conforms to ASTM D7690 Standard Practice for Microscopic Characterization of Particles from In-Service Lubricants by Analytical Ferrography. Periodic in-service lubricant samples are collected from a machine or engine as part of routine condition monitoring program. A ferrogram is prepared from the sample to separate particles from sample fluid. The ferrogram is subsequently examined using an optical microscope to identify the types of particles present to aid in identifying the wear mode occurring in the oil-wetted path of the machine.

Send Email Details -

ASTM D1840 Naphthalene Hydrocarbons in Aviation Turbine Fuels

KN-UV-VIS Spectrometer conforms to ASTM D1840 Standard Test Method for Naphthalene Hydrocarbons in Aviation Turbine Fuels by Ultraviolet Spectrophotometry. This test method for naphthalene hydrocarbons is one of a group of tests used to assess the combustion characteristics of aviation turbine fuels of the kerosene boiling range. The naphthalene hydrocarbon content is determined because naphthalenes, when burned, tend to have relatively larger contribution to a sooty flame, smoke, and thermal radiation than single ring aromatics.

Send Email Details