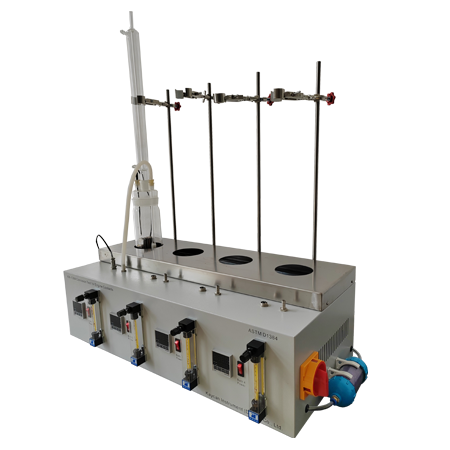

ASTM D2809 Apparatus for Cavitation Corrosion and Erosion-Corrosion Characteristics

Brand KN

Product origin Dalian

Delivery time 30 days after receiving full TT payment

Supply capacity 10 sets / month

KN-2809 Apparatus for Cavitation Corrosion and Erosion-Corrosion Characteristics conforms to ASTM D2809 Standard Test Method for Cavitation Corrosion and Erosion-Corrosion Characteristics of Aluminum Pumps with Engine Coolants. This test method can be used to distinguish between coolants that contribute to cavitation corrosion and erosion-corrosion of aluminum automotive water pumps and those that do not. It is not intended that a particular rating number, as determined from this test, will be equivalent to a certain number of miles in a vehicle test; however, limited correlation between bench and field service tests has been observed with single-phase coolants. Field tests under severe operating conditions should be conducted as the final test if the actual effect of the coolant on cavitation corrosion and erosion-corrosion is to be appraised. It is also possible, with proper control of the test variables, to determine the effect of pump design, materials of construction, and pump operating conditions on cavitation corrosion and erosion-corrosion damage.

KN-2809 Apparatus for Cavitation Corrosion and Erosion-Corrosion Characteristics

Overview

KN-2809 Apparatus for Cavitation Corrosion and Erosion-Corrosion Characteristics conforms to ASTM D2809 Standard Test Method for Cavitation Corrosion and Erosion-Corrosion Characteristics of Aluminum Pumps with Engine Coolants. This test method can be used to distinguish between coolants that contribute to cavitation corrosion and erosion-corrosion of aluminum automotive water pumps and those that do not. It is not intended that a particular rating number, as determined from this test, will be equivalent to a certain number of miles in a vehicle test; however, limited correlation between bench and field service tests has been observed with single-phase coolants. Field tests under severe operating conditions should be conducted as the final test if the actual effect of the coolant on cavitation corrosion and erosion-corrosion is to be appraised. It is also possible, with proper control of the test variables, to determine the effect of pump design, materials of construction, and pump operating conditions on cavitation corrosion and erosion-corrosion damage.

Features

Motor, used for driving the cooling liquid circulation, connected to the water pump

Water pump, imported brand base on ASTM D2809 requirements

Vacuum pressure gauge: Digital display the real time vacuum degree of the pump inlet

Throttling valve, for adjusting the water pump flow rate

Heater, for heating the cooling liquid to the test temperature

Liquid storage tank, storing the cooling liquid for the pipeline system

Heat exchanger, for supplying the 35~38℃ test temperature by heat exchanging of the cooling water.

Regulating valve, 3 valves for adjusting the vacuum degree and test pressure

Pressure gauge, display the real time pressure value

Expansion chamber, steam expansion device

Technical parameters

Applicable standard: ASTM D2809

Ambient requirements: Temperature 20~25℃, Relative Humidity<60%

Pump body rotate speed; 0~4600±100r/min

Fuse: 20A

Temperature control range<650℃

Temperature accuracy: ±0.1℃

Flow rate range: 0~20ml/min

Flow rate control accuracy: ±5%

Rated voltage: AC220V, 50Hz

Total power: 6.5KW