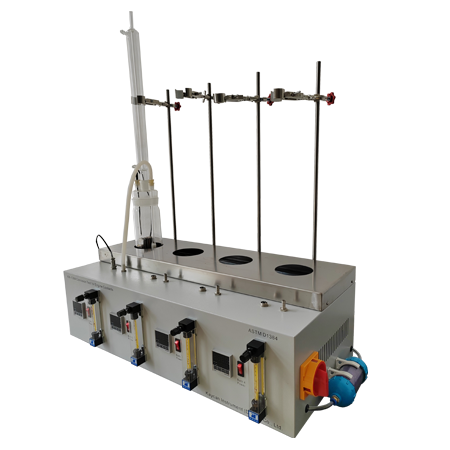

ASTM D2570 Simulated Service Corrosion Tester

Brand KN

Product origin Dalian

Delivery time 30 days after receiving full TT payment

Supply capacity 10 sets / month

KN-2570 Simulated Service Corrosion Tester conforms to ASTM D2570 Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants. An engine coolant is circulated for 1064h at 88℃ (190℉) in a flow loop consisting of a metal reservoir, an automotive coolant pump, an automotive radiator, and the connecting rubber hoses. Test specimens representative of engine cooling system metals are mounted inside the reservoir, which simulates an engine cylinder block. At the end of the test period, the corrosion-inhibiting properties of the coolant are determined by measuring the mass losses of the test specimens and by visual examination of the interior surfaces of the components.

KN-2570 Simulated Service Corrosion Tester

Overview

KN-2570 Simulated Service Corrosion Tester conforms to ASTM D2570 Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants. An engine coolant is circulated for 1064h at 88℃ (190℉) in a flow loop consisting of a metal reservoir, an automotive coolant pump, an automotive radiator, and the connecting rubber hoses. Test specimens representative of engine cooling system metals are mounted inside the reservoir, which simulates an engine cylinder block. At the end of the test period, the corrosion-inhibiting properties of the coolant are determined by measuring the mass losses of the test specimens and by visual examination of the interior surfaces of the components.

Features

1. Consists of operation parts, display, heating control, speed control, pressure control, flow rate control and necessary spare parts

2. Motor: For driving the coolant circulation, connected to the water pump

3. Water pump: For offering the required circulating flow rate

4. Condenser: For decreasing the test pressure, simulates the car working condition

5. Reservoir: For placing the metal test specimens

6. Glass tube: For observing the circulating status

Technical parameters

1. Applicable standard: ASTM D2570

2. Ambient requirements: 20~25℃, Humidity<60%

3. Fuse: 20A

4. Temperature control accuracy: ±3℃

5. Temperature measuring accuracy: 0.1℃

6. Temperature control range: Ambient~88℃

7. Flow rate control range: 0~95L/min

8. Flow rate control accuracy: ±5%

9. Rated Voltage: AC220V, 50Hz

10. Power: 7000W