-

Hot

ASTM D5800 Evaporation Loss Of Lubricating Oils By The Noack Method

The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable evaporation loss. Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications.

Send Email Details -

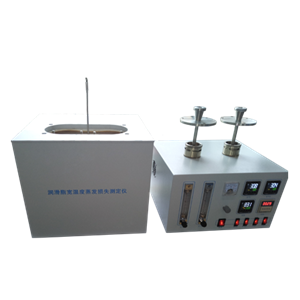

ASTM D2595 Lubricating Grease Wide Temperature Range Evaporation Loss Tester

KN-2595 Lubricating Grease Wide Temperature Range Evaporation Loss Tester conforms to ASTM D2595 Standard Test Method for Evaporation Loss of Lubricating Greases Over Wide-Temperature Range. A weighed sample of grease in an evaporation cell is placed in a heating device maintained at the desired test temperature. Heated air is passed over the grease surface for 22h±0.1h. The loss in weight of the sample due to evaporation is determined.

Send Email Details -

ASTM D1384 Corrosion Test For Engine Coolants In Glassware

this test method will generally distinguish between coolants that are definitely deleterious from the corrosion standpoint and those that are suitable for further evaluation.however, the results of this test method cannot stand alone as evidence of satisfactory corrosion inhibition. the sctual serivice value of an engine coolant formulation can be determined only by more comprehensive bench,hynamometer,and field tests

Send Email Details -

ASTM D6079 Evaluating Lubricity Of Diesel Fuels By The HFRR

Diesel fuel injection equipment has some reliance on lubricating properties of the diesel fuel. Shortened life of engine components, such as diesel fuel injection pumps and injectors, has sometimes been ascribed to lack of lubricity in a diesel fuel

Send Email Details -

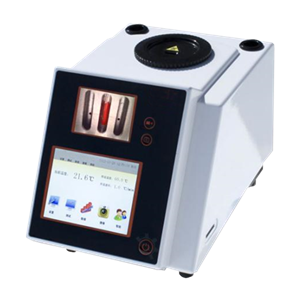

ASTM D87 Automatic Petroleum Wax Melting Point Apparatus

KN-87Z Automatic Petroleum Wax Melting Point Apparatus (Cooling Curve Method) conforms to ASTM D87 Standard Test Method for Melting Point of Petroleum Wax (Cooling Curve), it covers the determination of the melting point (cooling curve) of petroleum wax. It is unsuitable for waxes of the petrolatum group, microcrystalline waxes, or blends of such waxes with paraffin wax or scale wax.

Send Email Details -

ASTM D938 Congealing Point of Petroleum Waxes and Petrolatum

KN-938 Congealing Point of Petroleum Waxes and Petrolatum conforms to ASTM D938 Standard Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum. Congealing point is a wax property that is of interest to many petroleum wax consumers. The procedure described here measures the temperature at which a sample being cooled develops a “set” or resistance to flow. At that temperature, the wax may be at or close to the solid state, or it may be semisolid and quite unctuous, depending on the composition of the wax or petrolatum being tested. In the case of petrolatums, congealing property is associated with the formation of a gel structure as the sample cools. A sample of wax is melted and a droplet is made to adhere to the bulb of a thermometer. Using a prewarmed flask as an air jacket, the droplet on the bulb is allowed to cool at a fixed rate until it congeals. The congealing point is observed as the temperature at which the droplet ceases to flow as the thermometer is turned.

Send Email Details -

ASTM D127 Petroleum Wax Drop Melting Point

Melting point is a wax property that is of interest to most wax consumers. It can be an indication of the performance properties of the wax. Drop melting point, Test Method D127, is often used to measure the melting characteristics of petrolatums and other high viscosity petroleum waxes

Send Email Details -

ASTM D2872 Rolling Thin Film Oven Test

this oven indicates approximate change in properties of asphalt during conventional hot-mixing ar about 150℃ as indicated by viscosity and other rheological measurements.it yields a residue which approximates the asphalt condition as incorporated in the pavement.if the mixing temperature differs appreciably from the 150℃ level. more or less effect on properties will occur. this oven also can be used to determine mass change,which is a measure of asphalt volatility

Send Email Details