-

Hot

Automatic Oxidation Stability Bath, RPVOT / RBOT / TFOUT

KN-OXIDATE Metal Bath Oxidation Stability Tester conforms to ASTM D2112 Standard Test Method for Oxidation Stability of Inhibited Mineral Insulating Oil by Pressure Vessel, ASTM D2272 Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel, ASTM D4742 Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT) and ASTM D942 Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure Vessel Method. It determines oxidation stability of new and in-service turbine oils and other industrial oils; it is field-proven non-liquid RPVOT (formerly known as RBOT) instrument in the industry used for evaluating oxidation resistance over a broad range of oils and lubricants. Widely used for base oil comparisons and as a condition monitoring tool for turbine oils.

Send Email Details -

Hot

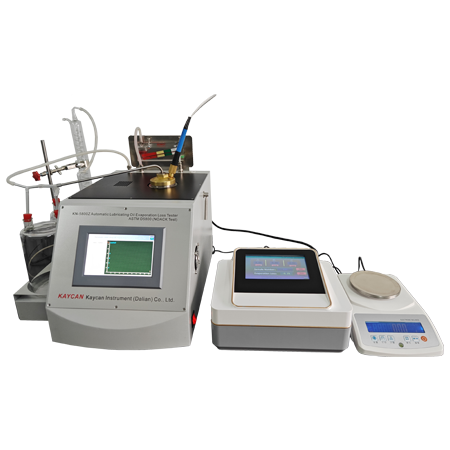

ASTM D5800 Evaporation Loss Of Lubricating Oils By The Noack Method

The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable evaporation loss. Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications.

Send Email Details -

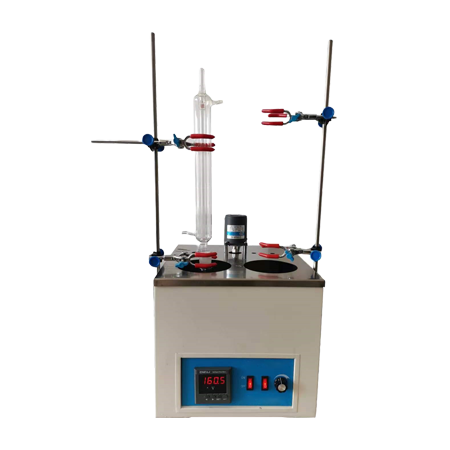

ASTM D130 Metal Bath Copper Strip Corrosion Tester

KN-130J Metal Bath Copper Strip Corrosion Tester conforms to the ASTM D130 Standard Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test and ASTM D4048 Standard Test Method for Detection of Copper Corrosion from Lubricating Grease. This tester is suitable for testing aviation gasoline, jet fuel, motor gasoline, natural gasoline, or other hydrocarbons with Reid vapor pressure not exceeding 124kPa (930mmHg), solvent oil, kerosene, diesel, distillate fuel oil, lubricating oil, grease, and other petroleum product.

Send Email Details -

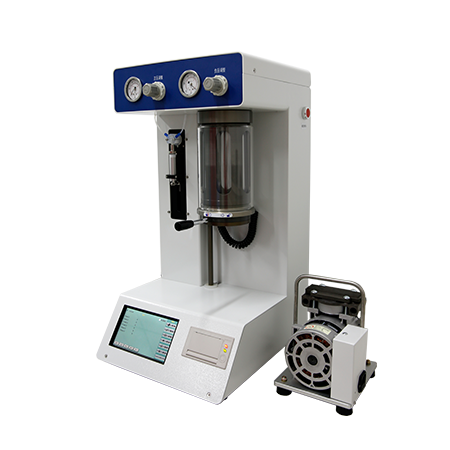

ASTM D3427 Air Release Properties Of Hydrocarbon Based Oils

Agitation of lubricating oil with air in equipment, such as bearings, couplings, gears, pumps, and oil return lines, may produce a dispersion of finely divided air bubbles in the oil. If the residence time in the reservoir is too short to allow the air bubbles to rise to the oil surface, a mixture of air and oil will circulate through the lubricating oil system. This may result in an inability to maintain oil pressure (particularly with centrifugal pumps), incomplete oil films in bearings and gears,and poor hydraulic system performance or failure.

Send Email Details -

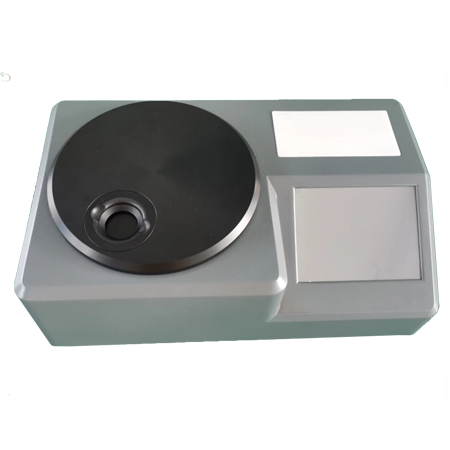

ASTM D8184 Particle Quantifier Instrument for Ferrous Wear Debris

KN-8184 Particle Quantifier Instrument for Ferrous Wear Debris conforms to ASTM D8184 Standard Test Method for Ferrous Wear Debris Monitoring in In-Service Fluids Using a Particle Quantifier Instrument. This test method is intended for the application of PQ magnetometry in assessing the progression of wear in machinery, for example, engines and gearboxes, by trending the mass of ferrous debris in samples of lubricating oils or greases.

Send Email Details -

ASTM D94 Saponification Number Of Petroleum Products

A known mass of the sample is dissolved in a suitable solvent, such as butanone (methylethylketone), xylenes, or Stoddard Solvent, or a combination thereof (Warning— Extremely flammable. Vapors can cause flash fire), and is heated with a known amount of alcoholic potassium hydroxide (KOH). The excess alkali is titrated with standard acid, and the saponification number is calculated.

Send Email Details -

ASTM D6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer

KN-6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer conforms to ASTM D6481 Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy and ASTM D7751 Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis. This tester is used to test metal elements in oils like P, S, Cl, Ca, Ti, V, Cr, Mn, Fe, Ni, Cu Zn, PB, Mo, Ag, Cd, Sn, etc.

Send Email Details -

ASTM D1401 Automatic Water Separability Of Petroleum Oils And Synthetic Fluids

This test method provides a guide for determining the water separation characteristics of oils subject to water contamination and turbulence. It is used for specification of new oils and monitoring of in-service oils.

Send Email Details -

ASTM D892 Foaming Characteristics Of Lubricating Oils

The tendency of oils to foam can be a serious problem in systems such as high-speed gearing, high-volume pumping, and splash lubrication. Inadequate lubrication, cavitation, and overflow loss of lubricant can lead to mechanical failure. This test method is used in the evaluation of oils for such operating conditions.

Send Email Details -

ASTM D6082 High Temperature Foaming Characteristics Of Lubricating Oils

The tendency of oils to foam at high temperature can be a serious problem in systems such as high-speed gearing, high volume pumping, and splash lubrication. Foaming can cause inadequate lubrication, cavitation, and loss of lubricant due to overflow, and these events can lead to mechanical failure

Send Email Details -

NAS1638 Benchtop Oil Particle Counter

this oil particle counter equip with Built-in ISO4406,GB/T14039, NAS1638, JBT9737.1, SAE749D, GJB420A,GJB420B, DL/T1096 particulate contamination level standards and user-defined particle channel settings; can built-in required standard according to user requirements;

Send Email Details -

ISO4406 Portable Oil Particle Counter

this oil particle counter equip with Built-in ISO4406,GB/T14039, NAS1638, JBT9737.1, SAE749D, GJB420A,GJB420B, DL/T1096 particulate contamination level standards and user-defined particle channel settings; can built-in required standard according to user requirements;

Send Email Details