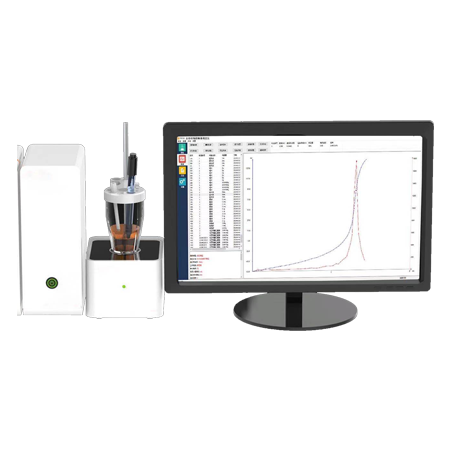

ASTM D7279 Automated Houillon Viscometer,B

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER RECEIVING FULL PAYMENT

Supply capacity 30 sets/month

KN-7929B Automated Houillon Viscometer conforms to ASTM D7279 Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer. Many petroleum products and some non-petroleum products are used as lubricants in the equipment, and the correct operation of the equipment depends upon the appropriate viscosity of the lubricant being used. Additionally, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

KN-7279B Automated Houillon Viscometer

Overview

KN-7929B Automated Houillon Viscometer conforms to ASTM D7279 Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer. Many petroleum products and some non-petroleum products are used as lubricants in the equipment, and the correct operation of the equipment depends upon the appropriate viscosity of the lubricant being used. Additionally, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

The viscosity of used oils is a commonly determined parameter in the oil industry to assess the effect of engine wear on the lube oils used, as well as the degradation of the engine parts during operation.

The Houillon viscometer tube method offers automated determination of kinematic viscosity. Typically a sample volume of less than 1mL is required for the analysis.

Features

Fast analysis, be able to get the results within 15s under the fast analysis mode. The results are generally obtained within 3 minutes. The whole process of sample injection, test, cleaning, drying, and result calculation generally takes no more than 7 minutes.

High automation. Be able to work continuously. Test, cleaning, drying, and result calculation are all done automatically

Be able to test transparent and opaque samples, including gasoline, diesel, kerosene, cutting fluid, heat transfer oil, additives, new oil for lubricating oil and oil in use and other Newtonian liquids

The measurement data is accurate. The tester has the function of secondary accurate quantification, automatically cuts the sample liquid column, precisely controls the sample volume, and no longer relies on micropipette quantification, avoids the limitations and deviations of pipette quantification, and ensures accurate data

Fully automatic cleaning, fast cleaning and low cleaning cost. A cleaning process generally consumes no more than 10 ml cleaning solution

The software is intelligent and user-friendly. Automatically select viscometers, rationally allocate sample test sequences, add samples, delete samples, and prioritize tests at any time. Automatically calculate the viscosity index if the conditions are met.

Many auxiliary functions: constant calibration, temperature calibration, internal clock timing verification, automatic conversion of kinematic viscosity to Enn's viscosity

Software and hardware dual over-temperature protection, over-temperature alarm function, anti-dry burning protection function, cleaning agent liquid level, waste liquid level alarm function

Adopts double-layer glass cylinder, the temperature is more uniform. Different temperature points can be tested and cleaned at the same time without affecting each other. Quick viscometer replacement without emptying the bath

Equipped with an air source power cabinet, once the test is completed, cleaning will be done at once

Adopt micro automatic sampling system, low failure rate, smooth sample injection, and small vibration

Adopts PT1000 high-precision temperature sensor, the temperature of the constant temperature bath is stable and accurate, and the temperature control accuracy reaches 0.005 ℃

Adopts advanced optical fiber amplifier, high temperature packaged optical fiber, it features higher signal stability and accuracy

Windows operating system, simple operation, friendly man-machine interface, can be connected to LIMS system, can be connected to an external scan code gun, and automatically enter sample information

It can be equipped with a disposable filter, which greatly reduces the workload of the operator on sample pretreatment

Technical parameters

Rated voltage: AC220V±10% 50Hz

Ambient temperature: 10~28℃

Relative humidity<80%

Measuring range: 0.3~6000mm²/s, the measuring span of two viscometers is 100 times

Sample volume: 0.3~1ml

Bath capacity: 2L*2

Temperature control range: 20~100℃(chiller is optional, if the expected temperature is lower than 40℃)

Temperature control accuracy: 0.005℃

Timing accuracy: 0.01s

Repeatability: ≤0.05%

Total power: ≤600W

Dimension: 350*640*600mm

There should be no strong vibration, airflow, strong electromagnetic interference and corrosive gas around the laboratory