ASTM D5185 Multielement By ICP

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets per month

22 elements in used lubricating oils and in base oils, and it provides rapid screening of used oils for indications of wear. Test times approximate a few minutes per test specimen, and detectability for most elements is in the low mg/kg range. In addition, this test method covers a wide variety of metals in virgin and re-refined base oils. Twenty-two elements can be determined rapidly, with test times approximating several minutes per test specimen.

KN-5185 ICP for used Lube Oils

Overview

In the daily work and production process, some special components are often protected, so it is necessary to regularly monitor the accumulation of wear particles on these components, which is often the analysis of metal elements in oil, based on the composition of metal components And the accumulation rate in the oil can accurately determine the failure cycle of the machine components. In addition, lubricating oil also needs to monitor its foreign contamination components (such as metal elements brought in by dust and dirt). Determining the content of wear metal in the lubricant can accurately understand the operating status and performance of the equipment. The metal contained in the oil shows the severity of the wear of the parts, which is very important for the maintenance of the equipment and the evaluation of the working performance. Monitoring methods for the determination of trace metals in lubricating oils as a component of wear are particularly important.

Talbe1. Main Technical Parameters of KN-5185

High Frequency Generator | |

Working Frequency | 27.12MHz |

Stability | ﹤0.05% |

Output power | 800W ~1600W |

Stability | ≤0.05% |

Matching Method | Automatic |

Scanning spectrometer | |

Light path | Czerny turner |

Focal length | 1000mm |

Raster specification | Ion-etched holographic grating, engraved line density 3600L / mm or 2400L / mm; scribed area (80 × 110) mm |

Line dispersion reciprocal | 0.26nm/m |

Resolution | ≤0.008nm(3600 wire grating) |

≤0.015nm(2400 wire grating) | |

Main host Parameters | |

Scanning wavelength range | 195nm~500nm(3600L/mm wire grating) |

195nm~800nm(2400L/mm wire grating) | |

Repeatability | RSD≤1.5% |

Stability | RSD≤2.0% |

Test Part

Abrasion Elements in Lube Oils

1.1.1 CONOSTAN Dedicated Diluent for ICP

1.1.2 Pipette,0-5ml

1.1.3 Electronic balance, 0.0001

1.2 Working Condition Requirements

High frequency generator: 27.12MHz, 0.7mm quartz torch with center channel, high frequency power 1200W, plasma gas flow 15L / min, auxiliary gas flow 0.99L / min, carrier gas flow 0.35L / min, oxygen flow rate 50ml / min , The temperature of the atomizing chamber is -20 ° C, and the speed of the peristaltic pump is 3ml / min.

1.3 Test method

After the apparatus is automatically ignited and the parameters are set according to the working

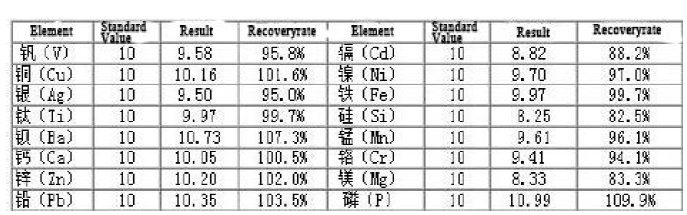

conditions of the apparatus, the diluent is directly sucked into the mist chamber through the nebulizer and enters the plasma. After the apparatus is stable, measure the blank solution, standard solution and diluted sample solution at one time. The content of each element in the final sample can be directly obtained. The linear relationship of the elements was determined according to the experimental method. At the same time, the blank solution was measured 10 times for each element. The standard deviation of the measured value was divided by the slope of the curve as the method detection limit. As can be seen from the table below, the fitting coefficient of the elemental working curve is higher than 0.999, indicating that the linear

relationship is good within the linear range of the working curve. Because the working parameters of the apparatus are optimized, the test conditions of the elements are optimized to improve the accuracy of the test results.

ICP Repeatability of 16 Elements in Lubricants

Results of GBW (E) 130129-Lubricant Metal Content Spectral Analysis Standard Materials (mg / kg)

Results of GBW (E) 130132-Lubricant Metal Content Spectral Analysis Reference Material (mg / kg)

Applicable Standard: ASTM D5185 Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

Conclusion

The ICP method is used to directly determine the 16 kinds of wear elements in lubricating oil. The relative digestion method has higher accuracy and better reproducibility. KN-5185 has the characteristics of low cost, fast speed and high accuracy. The determination of 16 types of wear elements in lubricating oil can fully meet the demands in the petrochemical industry.

Test Report Comparison | |||||||

Sample Name | Diesel Engine Oil | ||||||

Receiving Date | JAN,2ND,2020 | Test Period | JAN,8TH,2020 | ||||

Description | Viscous Oil Sample | ||||||

Test Requirement | |||||||

Test component | Ca, Mg, P, Zn | ||||||

Reference | |||||||

Standard | ASTM D5185 | Standard Sample | S-21 Mixed Sample | ||||

Humidity | ≤70% | Temperature | 25℃ | ||||

Test Process | |||||||

Weigh a certain amount of sample into a 100ml volumetric flask, add the internal standard solution, dilute to the mark with blank oil, shake well, and wait for measurement | |||||||

KN-5185 ICP | Perkin Elmer Optima 3300 ICP-OES | ||||||

Test Item | Unit | Result | Test Item | Unit | Result | ||

Ca | mg/kg | 4179.1 | Ca | mg/kg | 4225.7 | ||

Mg | mg/kg | 22.06 | Mg | mg/kg | 21.501 | ||

P | mg/kg | 1064.3 | P | mg/kg | 1026.2 | ||

Zn | mg/kg | 1133.1 | Zn | mg/kg | 1133.1 | ||