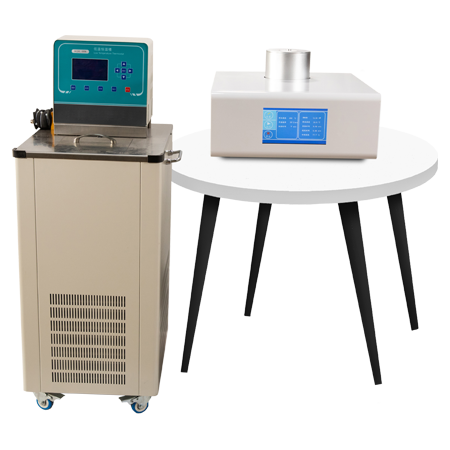

ASTM D4419 Low Temperature Differential Scanning Calorimeter

Brand KN

Product origin Dalian

Delivery time 30 days after receiving full payment

Supply capacity 30 sets/ month

KN-4419 Low Temperature Differential Scanning Calorimeter conforms to ASTM D4419 Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry (DSC). DSC in a convenient and rapid method for determining the temperature limits within which a wax undergoes during transitions. The highest temperature transition is a solid-liquid transition associated with complete melting; it can guide the choice of wax storage and application temperatures. The solid-solid temperature transition is related to the properties of the solid, that is, hardness and blocking temperature.

KN-4419 Low Temperature Differential Scanning Calorimeter

Overview

KN-4419 Low Temperature Differential Scanning Calorimeter conforms to ASTM D4419 Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry (DSC). DSC in a convenient and rapid method for determining the temperature limits within which a wax undergoes during transitions. The highest temperature transition is a solid-liquid transition associated with complete melting; it can guide the choice of wax storage and application temperatures. The solid-solid temperature transition is related to the properties of the solid, that is, hardness and blocking temperature.

Instrument purpose

Measure the physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, crystallization and crystallization heat, phase transition reaction heat, thermal stability of products, curing / cross linking, oxidation induction period, etc.

Features

The new fully enclosed metal furnace design structure greatly improves the resolution and resolution as well as better baseline stability.

Adopt professional alloy sensor, more corrosion resistance, oxidation resistance, high sensor sensitivity.

Perfect two-way atmosphere control system, precise control of purge gas flow, automatic switching of software settings, data directly recorded in the database.

With Cortex-M3 core arm controller, the operation speed is faster and the temperature control is more accurate.

USB two-way communication is adopted, which is more convenient to operate and supports the function of self recovery connection.

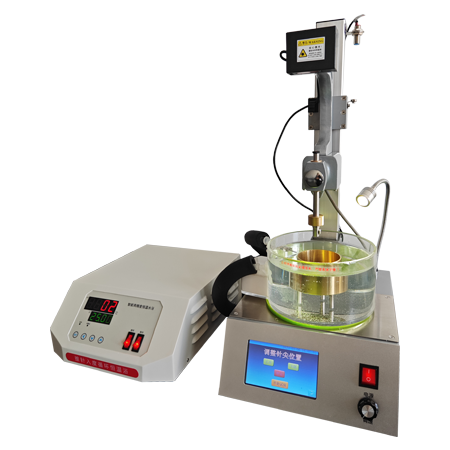

The 7-inch 24 bit color full-color LCD touch screen is used to display the status and data of the instrument in real time.

The instrument is equipped with standard materials, and users can calibrate each temperature section by themselves, so as to reduce the error of the instrument.

Intelligent software design, automatic drawing of the whole process of the instrument, software can realize various data processing, such as calculation of enthalpy, glass transition temperature, oxidation induction period, melting point and crystallization of substances, etc.

Technical parameters

DSC range: 0~±500mW

Temperature range: -40℃~600℃ Refrigeration by low temperature constant temperature device 3.

Temperature resolution: 0.01℃

Heating rate: 0.1~80℃/min

Cooling rate: 0.1~50℃/min

Temperature repeatability: ±0.1℃

DSC Noise: 0.01mW

DSC Resolution: 0.01mW

DSC accuracy: 0.01mW

DSC sensitivity: 0.1mW

Temperature control mode: heating, cooling, constant temperature, any combination of three modes for recycling

Curve scan: temperature rise scan

Atmosphere control: automatic switching of instrument

Gas flow: 0-200mL/min

Gas pressure: 0.2MPa

Display mode: 24 bit color 7 inch LCD touch screen display

Data interface: standard USB interface

Parameter standard: equipped with reference material, with one button calibration function, user can self calibrate temperature and enthalpy

Working power supply: AC 220V 50Hz or customized

Power: 300W