ASTM D1404 Deleterious Particles In Lubricating Grease

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets per month

The significance of the number of scratches as far as correlation with field performance is concerned has not been established. A particle which is abrasive to plastic will not necessarily be abrasive to steel or other bearing materials. Some correlation was obtained in that the contaminant used in Sample 3 had a greater wear rate in a laboratory ball bearing abrasive wear test than the contaminant in Sample 2.

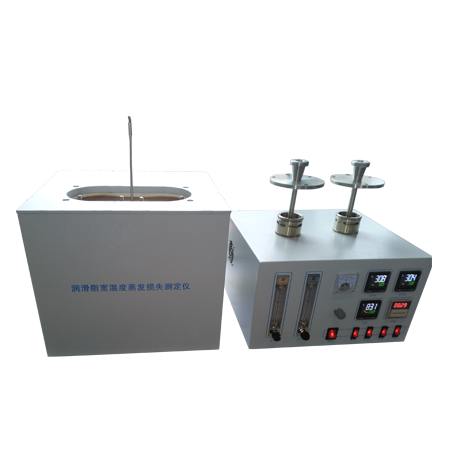

KN-1404 Deleterious Particles Determination Apparatus

Overview

KN-1404 Deleterious Particles Determination Apparatus conforms to ASTM D1404 Standard Test Method for Estimation of Deleterious Particles in Lubricating Grease. It is used to detect and estimate deleterious particle contamination in lubricating greases and other semi-solids and heavy liquids. Grease fillers can be tested for abrasive contaminants by first mixing them into petrolatum or grease known to be free of deleterious particles. A small portion of the lubricating grease sample is placed between two clean, highly polished acrylic-plastic plates held rigidly and parallel in metal holders. A pressure of 200 psi [1.38 MPa] is applied, and one plate is rotated 30° relative to the other. Particles harder than the plastic and exceeding in size the distance between the plates will imbed in the plates and cause characteristic, arc-shaped scratches in the plates. The relative number of such solid particles can be estimated by counting the total number of arc-shaped scratches on the two plates.

Apparatus information

Conforms to ASTM D1404 specifications

Complete apparatus per Figure 1 and 2 of ASTM D1404.

Rotates plastic plate 30° against stationary plate while applying 200psi pressure.

Includes body, test plate holders, loading screw, calibrated spring with scale for applying test load and removable cap assembly with milled slot and handle for rotating test plates.

Constructed of stainless steel. Order plastic test plates separately.