-

Hot

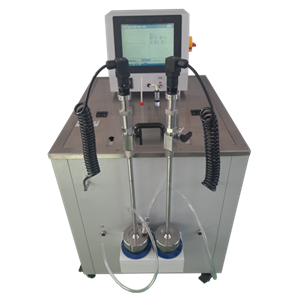

ASTM D4683 Viscosity At High Temperature And High Shear Rate By Tapered Plug Viscometer

KN-4683 Apparatus for Viscosity by TBS conforms to ASTM D4683 Standard Test Method for Measuring Viscosity of New and Used Engine Oils at High Shear Rate and High Temperature by Tapered Bearing Simulator Viscometer at 150 °C and ASTM D4741 Standard Test Method for Measuring Viscosity at High Temperature and High Shear Rate by Tapered-Plug Viscometer. The ASTM D4683 covers the laboratory determination of the viscosity of engine oils at 150℃ and 1.0·106s-1 using a viscometer having a slightly tape

Send Email Details -

ASTM D2170 Viscosity Of Asphalts By Vacuum Capillary Viscometer

the kinematic viscosity characterizes flow behavior. the method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. the specifications are usually at temperature of 60 and 135℃.

Send Email Details -

-

ASTM D2171 Apparatus for Viscosity of Asphalts

KN-2171 Apparatus for Viscosity of Asphalts conforms to ASTM D2171 Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer. The viscosity at 60℃ characterizes flow behavior and may be used for specification requirements for cutbacks and asphalt binders. This time is measured for a fixed volume of the liquid to be drawn up through a capillary tube by means of vacuum, under closely controlled conditions of vacuum and temperature. The viscosity in Pascal-seconds is calculated by multiplying the flow time in seconds by the viscometer calibration factor.

Send Email Details -

ASTM D6278 Shear Stability Of Polymer Containing Fluids

This test evaluates the percent viscosity loss for polymer-containing fluids resulting from polymer degradation in the high shear nozzle device. Thermal or oxidative effects are minimized.

Send Email Details -

DIN 51350-6 Shear Stability Of Lubricating Oils Containing Polymers

This is KRL friction pair on a four-ball friction tester, uses SKF SKF 32008 tapered roller bearings to determine the shear stability of polymer-containing lubricants, including pressure fluids. The test results can be used to predict the permanent viscosity loss. The tap speed is 1500 rpm, the test force is 5000 Newtons, the temperature is 60 °C, the total number of revolutions is 1.74 million, the time is about 20 hours.

Send Email Details -

Oxidation Stability Bath, RPVOT / RBOT / TFOUT

The estimate of oxidation stability is useful in controlling the continuity of this property for batch acceptance of production lots having the same operation. It is not intended that this test method be a substitute for Test Method D943 or be used to compare the service lives of new oils of different compositions.

Send Email Details -

Hot

Automatic Oxidation Stability Bath, RPVOT / RBOT / TFOUT

KN-OXIDATE Metal Bath Oxidation Stability Tester conforms to ASTM D2112 Standard Test Method for Oxidation Stability of Inhibited Mineral Insulating Oil by Pressure Vessel, ASTM D2272 Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel, ASTM D4742 Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT) and ASTM D942 Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure Vessel Method. It determines oxidation stability of new and in-service turbine oils and other industrial oils; it is field-proven non-liquid RPVOT (formerly known as RBOT) instrument in the industry used for evaluating oxidation resistance over a broad range of oils and lubricants. Widely used for base oil comparisons and as a condition monitoring tool for turbine oils.

Send Email Details